Knowledge

How to Select and Erect the Right Scaffolding for Your Construction Project

Introduction to Scaffolding Selection

Selecting the appropriate scaffolding system is fundamental to success in any construction project. The right scaffolding not only ensures worker safety but also significantly impacts project efficiency and timelines. With the global construction industry evolving, understanding how to leverage international supply chains—particularly Chinese manufacturing capabilities and Uzbekistan's strategic supply advantages—has become increasingly valuable for project managers and contractors worldwide.

This comprehensive guide will walk you through the essential considerations for choosing, erecting, and maintaining scaffolding systems while highlighting how Chinese manufacturing quality combined with Uzbekistan's logistical advantages can benefit your projects.

Assessing Your Project Requirements

Before selecting scaffolding, conduct a thorough project assessment to determine your specific needs. Key factors to consider include:

Project Scope and Height Requirements: Evaluate the height of structures you'll be working on and the overall project scale. High-rise buildings demand scaffolding with robust designs capable of supporting workers at various heights.

Load Capacity Requirements: Calculate the combined weight of workers, materials, and equipment that the scaffolding must support. Each scaffolding type has defined weight capacities, and exceeding these limits can lead to structural failures.

Project Duration: Short-term projects might benefit from rental options, while long-term projects could justify purchasing scaffolding systems.

Site Conditions: Assess ground stability, space constraints, and environmental factors like weather conditions that might affect scaffolding performance.

Types of Scaffolding Systems

Understanding different scaffolding types is crucial for selecting the most appropriate system for your project:

Supported Scaffolding

The most common type, consisting of vertical poles and horizontal platforms. Ideal for painting, masonry, and general construction projects.

Suspended Scaffolding

Hung from roofs using ropes or wires, perfect for high-rise buildings and facade work. This system provides excellent access to difficult-to-reach areas.

Rolling Scaffolding

Mounted on castors for enhanced mobility, making it ideal for projects requiring frequent repositioning, such as painting or plastering across multiple sections.

Modular/System Scaffolding

Features pre-engineered components that fit together like building blocks, offering high customization for complex structures while reducing assembly time.

Advantages of Chinese-Manufactured Scaffolding

Chinese manufacturing has made significant strides in scaffolding production, offering several key advantages:

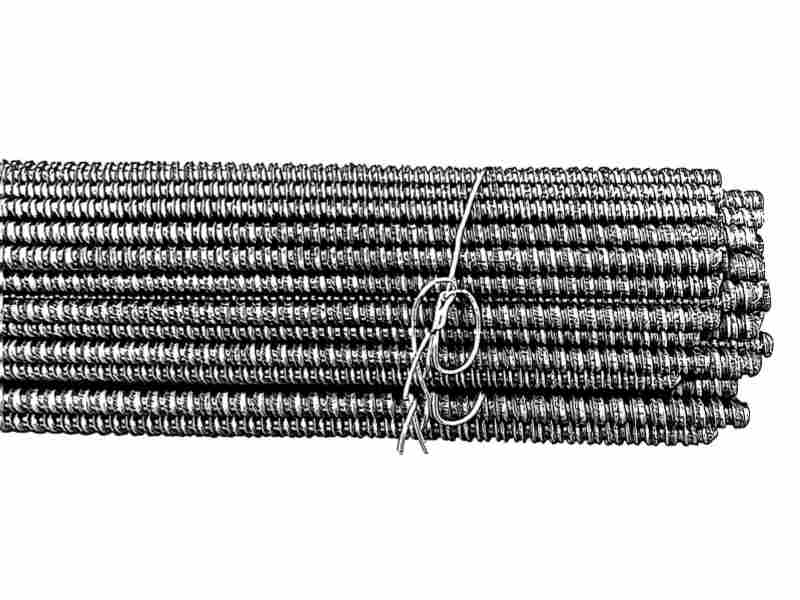

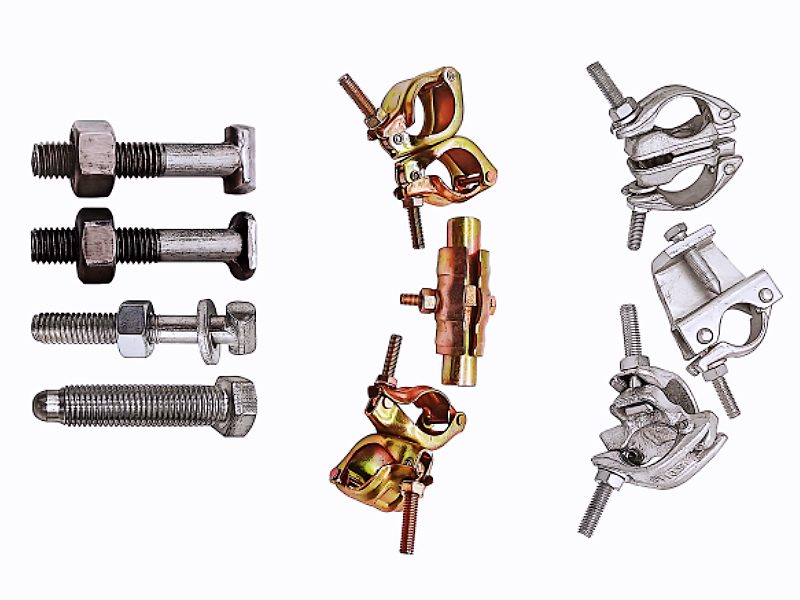

Quality Materials: Chinese manufacturers produce scaffolding from high-grade steel and aluminum alloys that meet international standards for strength and durability.

Advanced Production Techniques: Utilizing state-of-the-art manufacturing processes ensures consistent quality and precision engineering across all components.

Cost-Effectiveness: Competitive pricing without compromising quality makes Chinese-manufactured scaffolding an excellent value proposition.

Customization Capabilities: Chinese manufacturers can produce customized solutions tailored to specific project requirements.

Uzbekistan's Strategic Supply Advantages

Uzbekistan's emerging role in the scaffolding supply chain offers unique benefits:

Geographical Advantage: Strategically located along key trade routes, Uzbekistan facilitates efficient distribution to European and Asian markets.

Quality Assurance: Uzbek suppliers increasingly adhere to international quality standards, ensuring reliable component performance.

Logistical Efficiency: Established infrastructure enables timely delivery, reducing project downtime

.

Market Knowledge: Local expertise in regional requirements helps tailor scaffolding solutions to specific market needs.

Step-by-Step Scaffolding Erection Process

Proper installation is critical for scaffolding safety and performance. Follow these essential steps:

1. Site Preparation

Clear the area of debris and obstacles

Ensure the ground is level and stable

Use base plates or mud sills to distribute weight evenly on firm surfaces

2. Foundation Setup

Place base plates on a solid, level surface

Use adjustable base jacks on uneven terrain

Verify stability before proceeding with assembly

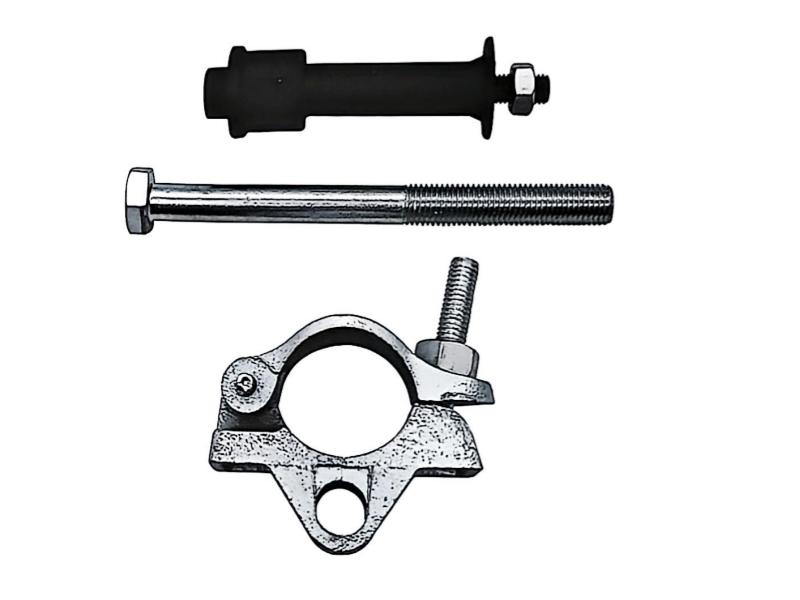

3. Frame Assembly

Erect frames and vertical supports according to manufacturer guidelines

Ensure all connections are secure

Regularly check for plumb and level placement

4. Bracing Installation

Install diagonal bracing to enhance rigidity and prevent sway

This step is crucial for supporting vertical loads and maintaining structural integrity

5. Platform Construction

Secure planks and platforms properly

Ensure even spacing and adequate overlap

Verify load capacity before use

6. Safety Features Installation

Install guardrails, midrails, and toeboards on all platforms above 2 meters

Implement fall protection systems as required

Safety Standards and Compliance

Adherence to safety standards is non-negotiable for scaffolding projects:

Regular Inspections: Conduct daily checks before use and after any event that might affect stability, such as severe weather

.

Load Management: Never exceed manufacturer's weight ratings, and distribute loads evenly across platforms.

Worker Training: Ensure all personnel are trained in proper assembly, use, and safety protocols.Compliance Verification: Confirm that scaffolding meets all relevant local and international safety standards.

Maintenance and Inspection Protocols

Implement a comprehensive maintenance program to ensure ongoing scaffolding safety:

Daily Visual Checks: Examine components for damage, wear, or corrosion before each use.Scheduled Professional Inspections: Engage certified inspectors for periodic thorough examinations, especially for long-term projects.

Proper Storage: Keep unused components in dry, secure areas to prevent damage.Documentation: Maintain records of all inspections, maintenance activities, and repairs.

Cost Considerations and Budget Optimization

Smart financial planning ensures you get the best value from your scaffolding investment:

Purchase vs. Rental Analysis: Evaluate whether buying or renting makes more economic sense based on project duration and frequency of use

.

Lifecycle Cost Assessment: Consider long-term expenses including maintenance, repair, and storage requirements.

Quality vs. Price Balance: While budget constraints are real, prioritize safety and durability over initial cost savings.

Conclusion: Optimizing Your Scaffolding Strategy

Selecting and erecting the right scaffolding involves careful consideration of multiple factors—from project-specific requirements to quality standards and budget constraints. By leveraging high-quality Chinese manufacturing and Uzbekistan's strategic supply capabilities, project managers can access cost-effective, reliable scaffolding solutions that meet international safety standards.

Remember that proper planning, adherence to safety protocols, and regular maintenance are essential components of successful scaffolding implementation. Whether working on a small residential project or a large commercial development, the right scaffolding approach will enhance safety, improve efficiency, and contribute significantly to project success.