Knowledge

What is Scaffolding? A Guide to Modern Construction Support Systems

Introduction

On construction sites worldwide, scaffolding serves as the silent backbone of every successful project. This temporary structure not only provides access to elevated areas but also ensures safety and efficiency. With the evolution of the global construction industry, scaffolding manufactured in China has been reshaping the market with its compelling value proposition.

What is Scaffolding?

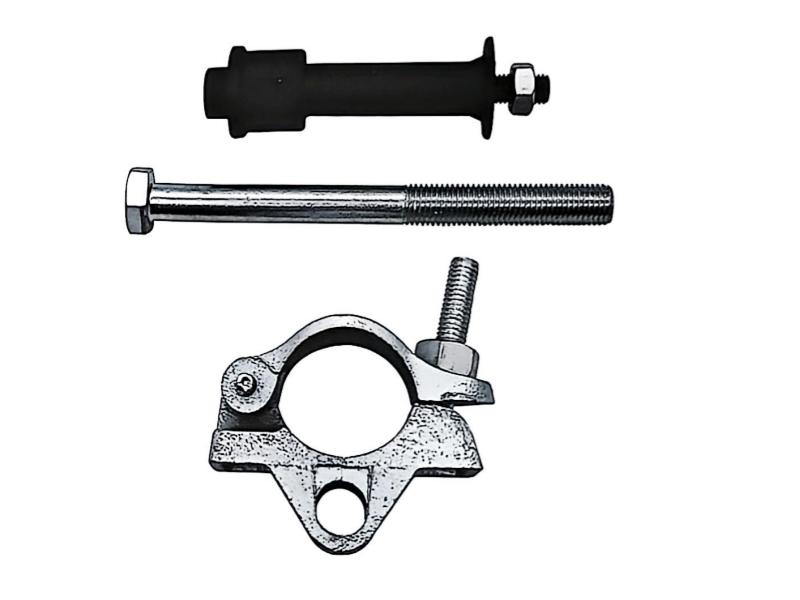

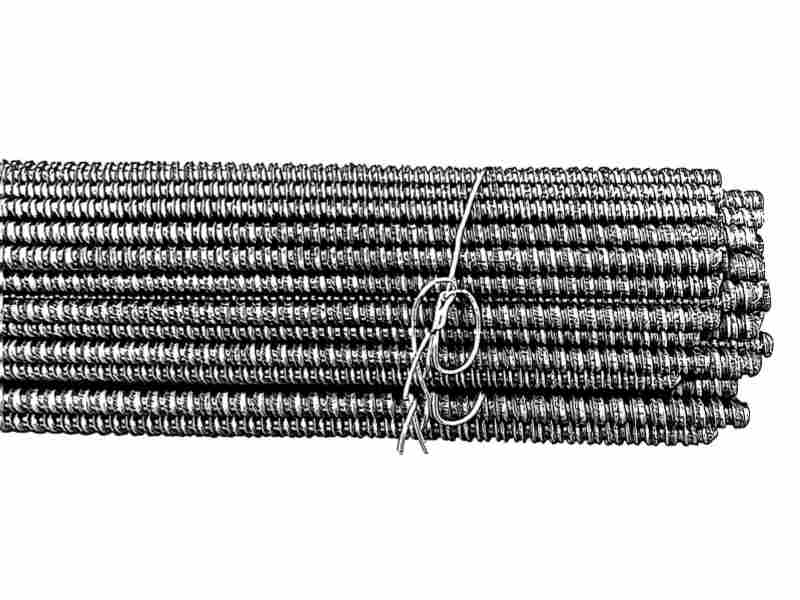

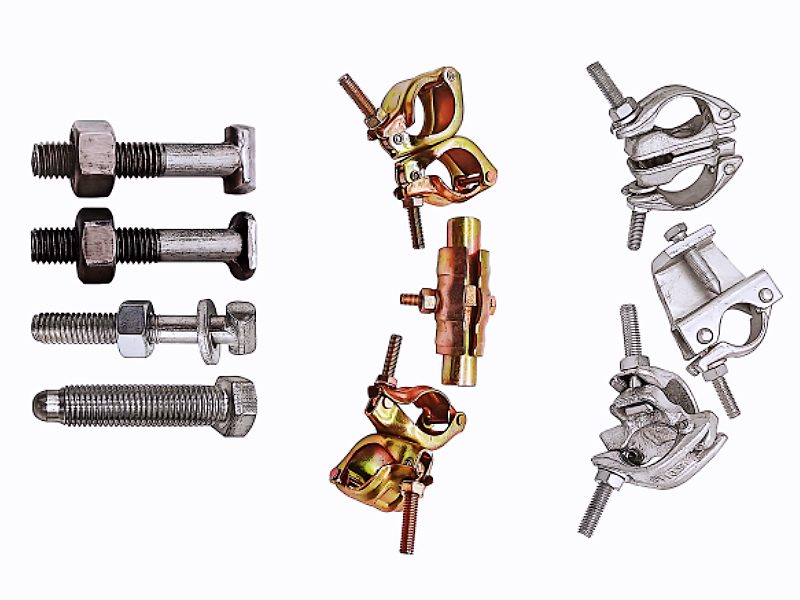

Scaffolding is a modular temporary structure used to support workers and materials during the construction, maintenance, or repair of buildings and other structures. Composed primarily of steel tubes, couplers, and platforms, it can be configured flexibly to meet project needs. Common types include:

Frame Scaffolding: Ideal for standard building structures

Modular System Scaffolding: Known for high load-bearing capacity and quick assembly

Tube and Coupler Scaffolding: Offers maximum flexibility for complex structures

Evolution in Quality and Safety

Modern scaffolding manufacturing adheres to stringent international standards such as EN 74 and BS 1139, which specify requirements for tube thickness, connection strength, and service life. Through computer-aided design and precision manufacturing processes, today’s scaffolding systems ensure:

Even load distribution

Reliable connection systems

Corrosion-resistant surface treatment

Intuitive assembly procedures

The Value of Scaffolding Sourced from China

1. Scalable Production Capacity

China’s integrated steel supply chain and automated production lines enable timely fulfillment of large-volume orders. Vertical integration from raw material sourcing to finished product delivery significantly reduces production costs.

2. Continuous Technological Innovation

Leading manufacturers invest 3–5% of annual sales in R&D, with notable advances in:

High-strength, lightweight materials

Anti-corrosion coating technologies

Modular connection systems

3. Rigorous Quality Control

Implementation of ISO 9001 standards and regular third-party inspections ensure compliance with international requirements. Many suppliers also hold CE, SGS, and other certifications, providing assurance of quality to global customers.

4. Competitive Pricing

Scaffolding manufactured in China often comes at a significant cost advantage compared to European counterparts, while maintaining comparable quality. This is achieved through:

Optimized production processes

Integrated logistics solutions

Economies of scale

Considerations for Selection

When procuring scaffolding, consider:

Project type and load requirements

Local safety regulations

Supplier certifications

After-sales service and technical support

Conclusion

When planning your next construction project, scaffolding sourced from China represents proven reliability. It combines engineering excellence with cost-effectiveness, supporting the sustainable development of the global construction industry.

This article is for reference only. Always consult a qualified engineer and adhere to local safety regulations when selecting and using scaffolding systems.